VILKEN TILLVERKNINGSMETOD PASSAR DINA BEHOV?

CNC-bearbetning är en subtraktiv tillverkningsmetod. Substitutet till subtraktiv tillverkning är additiv tillverkning och formativ tillverkning.

SUBTRAKTIV TILLVERKNING

Skärande bearbetning är en väldigt flexibel metod som är väldigt kostnadseffektiv på små till medelstora volymer.

Startkostnaden är på några tusenlappar då maskinerna måste ställas. Dock så blir det mycket spill av avfallsmaterial som måste återvinnas. På additiv- och formativ tillverkning så är det näst intill inget spill.

ADDITIV TILLVERKNING

Ett mer vanligt namn för additiv tillverkning är 3-dimensionel printing. 3D-printing klarar av mer komplicerade geometrier som de andra metoderna inte klarar av. Det är en effektivt metod vid prototyper av plaster då man behöver komponenterna snabbt.

Det går att printa i metaller med, men urvalet är litet och materialen är dyra.

FORMATIV TILLVERKNING

Formativ tillverkning innebär: gjutning, formsprutning, kall- och värmestukning. Dessa metoder använder formar som skapar komponenter. Det tar bara sekunder att tillverka bitarna.

Dessa formverktyg kostar runt 50 000 - 100 000 kronor, vilket gör startkostnaden väldigt hög.

Med denna höga startkostnad så lönar sig bara ordrar på höga och återkommande volymer.

SUBTRAKTIV TILLVERKNING

MEDEL

STARTKOSTNAD

ADDATIV TILLVERKNING

FORMATIV TILLVERKNING

LÅG

HÖG

SVÅRA GEOMETRIER

MEDEL

MEDEL

HÖG

FLEXIBILITET

HÖG

MEDEL

LÅG

SERIESTORLEKAR

10 - 10 000 ST

1 - 10 ST

10 000 ST <

VARIATION MATERIAL

HÖG

HÖG

LÅG

SPILLAVFALL

HÖG

LÅG

LÅG

TILLVERKNINGSTID/ ENHET

MINUTER

TIMMAR

SEKUNDER

LEDTIDER

MEDEL

LÅG

HÖG

Add a Title

OM OSS

OM OSS

VÅRA TYPER AV SKÄRANDE

BEARBETNING

Vid automatsvarvning så är inte den enda bearbetning svarvning som kan utföras. Dessa operationer kan man göra i en CNC-svarv och räknas till skärande bearbetning:

FRÄSNING

VAD ÄR FRÄSNING?

Fräsning likt svarvning skär bort material ifrån komponenten. Vid fräsning skär man dock bort materialet via ett roterande verktyg. Roterande verktyg innebär att det är verktyget som snurrar, jämfört med svarvning där arbetsstycket snurrar.

ARBETSSTYCKE

VERKTYG

Fördelen med att verktyget snurrar är att man kan skapa komplicerade geometrier som ett svarvverktyg inte klarar av.

PLANA YTOR

RUNDA YTOR

KANTIGA YTOR

ALLA VINKLAR

FRIA FORMER

"Det går att vinkla arbetsstycket i vilken vinkel du vill. Detta gör att du kan få fram komponenter med fria val av geometrier."

LÄTTRING

VAD ÄR LÄTTRING?

Lättring, även kallat lettring har sitt ursprung ifrån tryckning av bokstäver på mynt (Engelskans lettering). I dagens samhälle så innebär lättring att man trycker mönster eller räfflor på cylindriska metalliska ytor.

Räfflornas jobb är att skapa en struktur som är greppvänlig och ger friktion.

ARBETSSTYCKE

VERKTYG

När man lättrar så använder man sig av ett lettringsverktyg. Detta verktyg har antingen en eller två lettringstrissor, beroende på vilket mönster man vill ha.

KRYSSLÄTTRING

RAK LÄTTRING

OLIKA TYPER AV MÖNSTER:

FORMNING

VAD ÄR FORMNING?

Genom att använda ett formverktyg, så kan man forma materialet efter önskad skepnad. Denna metod är snabb och effektiv, jämfört med att svarva fram samma form.

Denna typ av verktyg används framförallt vid framställningen av munstycken för fluidflöden, hydraulik eller pneumatik, för att kontrollera flöden.

ARBETSSTYCKE

VERKTYG

Formverktyget formar grundmaterialet efter sin egen form när det pressas och skär mot metallen eller plasten.

Olika typer av munstycken/ nipplar:

-

CHASE NIPPEL

-

STRÖMNINGSMUNSTYCKE

-

SKRÄDDARSYDDA NIPPLAR OCH MUNSTYCKEN

GÄNGNING

VAD ÄR GÄNGNING?

En gänga är en spiralformad struktur som är till för att fästa ihop två olika komponenter med varandra genom en invändig gänga (hona) och en utvändig gänga (hane). Det är gängan som är grunden till fästelement.

En gänga kan man få vertikalt, horisontellt och diagonal.

INVÄNDIG GÄNGA

UTVÄNDIG GÄNGA

HORISONTELL

VERTIKAL

DIAGONAL

ALLA VINKLAR

Vi erbjuder alla slags gängor från standard till specialanpassade:

-

Vänster och höger gänga

-

Metriska gängor (M)

-

"UNIFIED"

-

Rörgänga (G)

-

NPT (konisk gänga)

HÅLBEARBETNING

VAD ÄR HÅLBEARBETNING?

Hål på en komponent kan ha många olika användningsområden så som gängor, sprintar, fluidflöden, genomgång av mekaniska komponenter, etcetera.

Man kan skapa ett hål genom att verktyget roterar eller att arbetsstycket roterar.

HORISONTELL

VERTIKAL

DIAGONAL

Olika typer av hålbearbetning:

-

BORRNING

-

BROTSCHNING

-

INVÄNDIG GÄNGNING

-

UTVÄNDIG GÄNGNING

ETT HÅL KAN ANTINGEN VARA GENOMGÅENDE ELLER TA SLUT MITT I KOMPONENETEN.

GENOMGÅENDE HÅL

BOTTENHÅL

SKRUVHUVUDEN

VAD ÄR SKRUVHUVUDEN?

För att få sitt fästelement att fungerar som det ska, behöver man någon typ av skruvhuvud/ grepp för att skruva åt skruven eller bulten.

TORX

FYRKANT

INSEX

SPÅR

INTERNT VERKTYGSGREPP

FYKANTS-HUVUD

SEXKANTS-HUVUD

EXTERNT VERKTYGSGREPP

BEROENDE PÅ ÄNDAMÅLET, ANVÄNDNINGSOMRÅDET OCH VERKTYG SÅ FINNS DET OLIKA TYPER AV GREPP:

MÄRKNING & GRAVERING

VAD ÄR MÄRKNING & GRAVERING?

Dagens samhälle blir det viktigare och viktigare med spårning. Med hjälp av att gravera eller märka dina komponenter så kan du öka spårbarheten.

DET FINNS TRE METODER FÖR ATT GRAVERA OCH MÄRKA:

-

MÄRKNING

-

STÄMPLING

-

GRAVERING

GENOM GRAVERING, STÄMPLING OCH MÄRKNING AV DIN KOMPONENT KAN DU FÅ:

-

SYMBOLER

-

TEXTER

DESSA SYMBOLER OCH TEXTER KAN I SIN TUR GE INFORMATION OM:

-

STORLEKAR

-

ARTIKELNUMMER

-

BATCHNUMMER

-

TRYCKHASTIGHET

-

SPECIFIKATIONER

-

TILLVERKNINGSLAND

-

STANDARDER

-

EGENANPASSADE TEXTER

VAD ÄR CNC-BEARBETNING?

CNC-bearbetning är en typ av skärande bearbetning, processen ingår i så kallad subtraktiv tillverkning. Subtraktiv tillverkning innebär att man avlägsnar material för att få sin önskade form i stället för att addera eller forma det som i additiv- och formativ tillverkning.

COMPUTER NUMERICAL CONTROL

CNC står för Computer Numerical Control och är själva hjärnan i en industrimaskin. Den mekaniska maskinen får nu digitala egenskaper som gör den smartare.

Datorn instruerar maskinen vad den ska göra och på det viset automatiseras processerna, vilket gör maskinen självgående.

CNC:n ger möjligheten för avancerade geometrier och en flexibel tillverkning. Detta gör att typen av komponenter du kan tillverka är oändliga och du kan få kundspecifika lösningar precis efter dina önskemål i alla seriestorlekar.

Den mekaniska delen av maskinen rör sig på så kallade axlar. Axlarna är som en räls som maskinens verktyg transporteras på och har stor precision, vilket gör att maskinen klarar av toleranser på 0,010 mm.

SKÄRANDE BEARBETNING

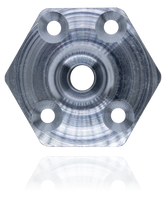

skärande bearbetning innebär att man använder ett skärande verktyg som avverkar/ skär bort och förädlar råmaterial som metaller och plast till en färdig geometrisk komponent som till exempel:

FÅ OFFERT DIREKT ONLINE

Slipp väntetider på offerter och få ett pris direkt online istället.

FRITT VAL AV MATERIAL & YTBEHANDLING

Välj material och ytbehandling efter din kravspecifikation.

SPECIALANPASSADE MÅTT

Anpassa måtten efter dina behov och krav.

HITTA BÄSTA LÖSNINGEN FÖR DIG

Laborera med antal, materialval och ytbehandlingar, så du hittar en lösning som passar just dig.

VAD ÄR CNC-BEARBETNING?

CNC-bearbetning är en typ av skärande bearbetning, processen ingår i så kallad subtraktiv tillverkning. Subtraktiv tillverkning innebär att man avlägsnar material för att få sin önskade form i stället för att addera eller forma det som i additiv- och formativ tillverkning.

CNC står för Computer Numerical Control och är själva hjärnan i en industrimaskin. Datorn instruerar maskinen vad den ska göra och på det viset automatiseras processerna, vilket gör maskinen självgående.

CNC:n ger möjligheten för avancerade geometrier och en flexibel tillverkning. Detta gör att typen av komponenter du kan tillverka är oändliga och du kan få kundspecifika lösningar precis efter dina önskemål i alla seriestorlekar.

Den mekaniska delen av maskinen rör sig på så kallade axlar. Axlarna är som en räls som maskinens verktyg transporteras på och har stor precision, vilket gör att maskinen klarar av toleranser på 0,010 mm.

skärande bearbetning innebär att man använder ett skärande verktyg som avverkar/ skär bort och förädlar råmaterial som metaller och plast till en färdig geometrisk komponent som:

FAQs

Vad menas med mekanisk bearbetning?

Mekanisk bearbetning avser en process där material, oftast metaller eller plast, bearbetas och skärs med hjälp av maskiner för att ge den önskade formen och ytfinish man har.

Det finns flera olika typer av skärande bearbetning mekaniska kompoenter:

Svarvning: Här roteras arbetsstycket medan ett skärande verktyg rör sig längs dess yta för att avlägsna material.

Fräsning: Ett roterande skärande verktyg (fräsen) rör sig över arbetsstycket för att ta bort material.

Borrning: Ett roterande borrverktyg används för att skapa hål i arbetsstycket.

Mekanisk bearbetning kan utföras på en mängd olika maskiner, vanligaste teknologin är CNC-maskiner (datorstyrd numerisk styrning) som kan programmeras att utföra komplexa bearbetningsoperationer med hög precision.

Huvudsyftet med mekanisk bearbetning är att omvandla ett råmaterial till en färdig produkt med specifika dimensioner och ytegenskaper.

Vad räknas till skärande bearbetning?

De bearbetningsprocesser som ingår i skärande bearbetning är: svarvning, fräsning, hålbearbetning, gängning, formning, lättring, driftning, gravering och stämpling