VAD ÄR VÄRME- & YTBEHANDLING?

Värme- och Ytbehandling är samlingsnamn på en metod som utförs på metaller och icke-metaller för att bemöta vissa kriterier. Dessa kriterier kan antingen vara av estetiska skäl, men görs vanligast för att öka hållbarheten genom att:

-

MOTVERKAR SLITAGE AV MATERIAL

-

SKYDDAR DET MOT NATURENS ELEMENT

-

ELEKTRISK ISOLATION

VARFÖR VÄRME- & YTBEHANDLING?

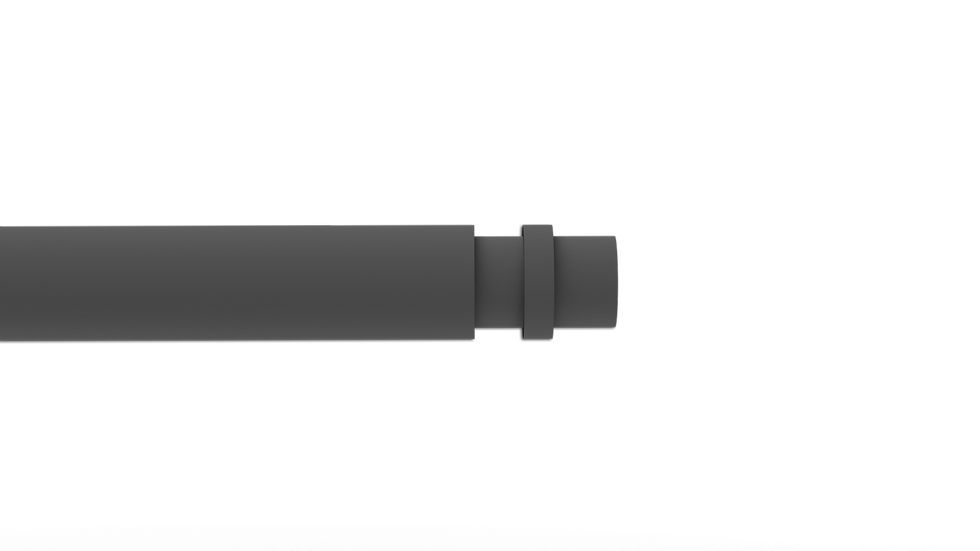

Man värmer- och ytbehandlar produkter för att ta fram vackra, hållbara och starka komponenter

KORROSION

När en metall är i sin naturliga form innan den bryts så har den olika mineralformer. När metallen bearbetas och mineralerna förädlas till en komponent, blir den inte lika stabil som i sin mineralform.

Rost även kallat korrosion är naturens sätt att få metallen att återgå till sin naturliga mineralform. En lösning på korrosionsproblem är att ytbehandla produkten.

Ytbehandling innebär att man på något sätt skapar ett skyddande lager mellan komponentens råa yta och naturens element, för att förhindra att mineralerna bryts ner.

ELEKTRICITET & VÄRME

Det är inte bara naturens krafter som kan bryta ner metaller, elektriciteten och höga temperaturer påverkar även det metall på ett negativt sätt.

De flesta metaller leder ström, detta är bra för ändamål som till exempel elkablar, men det är inte alltid som man vill att metallen ska vara strömförande.

För att motverka att metallen ska vara strömförande kan man täcka den med en yta som inte elektronerna tränger igenom och isolerar komponenten.

Elektronisk ytbehandling ger en skyddade hinna av krom, nickel eller zink.

Skulle man vilja att komponenten ska leda elektricitet bra, så kan man behandla materialet med en yta som: silver eller guld, vilket är väldigt strömförande.

FINISH

När en komponent blir behandlad för att bli starkare och hållbar, så kan den se ful ut.

Det är inte alltid hållbarheten som är viktig. Då många slutprodukter som bearbetas på Turnab når konsumenter, då är även estetiken viktig.

Det viktigaste kriterium är att de bearbetade komponenterna skyddas mot naturens element, men i vissa fall måste de även exponeras på ett sätt så den tillfredsställer betraktarens ögon.

RENA YTOR

En CNC-maskin använder olja för att kyla verktygen när de skär råmaterialet. Detta gör att den mekaniska komponenten är oljig, men har även rest-ämnen som spånor och andra partiklar. Detta kan inte blotta ögat se. Det är då viktigt att göra rent produkten, så den kan genomgå nästa process eller levereras till kund. Via rengöring får även detaljen ett tunt rostskydd som skyddar den under transport eller lagring.

SPINDELN I NÄTET

Genom vårt nätverk av leverantörer i närområdet, kan vi ombesörja värme- och ytbehandling på de komponenter vi bearbetar. Detta gör att du själv slipper hitta nya leverantörer. Detta leder till minskade frakter och högre kvalitet, det kallar vi hållbart!